The concept of 3D Printing was laid out by David E.H. Jones in 1974. However, methods and materials for fabricating models weren’t developed until the early 1980s.

The term ‘3D printing’ covers various methods and technologies used to create parts and products using different materials. These techniques have evolved greatly in recent years, playing important roles in many applications.

This overview article aims to explain the different types and processes of 3D Printing, how they work, and what are their uses and benefits in the current market. Let’s start with a very basic question.

Table of Contents

What Is 3D Printing?

3D Printing, also known as additive manufacturing, is a process of making a physical object from a three-dimensional digital model or a CAD model. It involves various computer-controlled techniques in which material is joined or solidified to build an actual object.

Typically, the material (such as powder grains or liquid molecules being fused together) is added layer by layer at the millimeter scale. This is why 3D Printing is also called an additive manufacturing process.

The image illustrates how a 3D printer prints three-dimensional objects layer by layer | 3D Logics

The image illustrates how a 3D printer prints three-dimensional objects layer by layer | 3D Logics

In the 1990s, 3D printing techniques were referred to as rapid prototyping. They were suitable only for the fabrication of aesthetic or functional prototypes. Since then, we have come a long way.

Today’s 3D printing technology, however, is advanced enough to create complex structures and geometries that would be otherwise impossible to build manually.

The precision, material range, and repeatability of 3D Printing have increased to the point that we can construct almost anything — from simple prototypes to complex final products such as eco-friendly buildings, aircraft parts, medical instruments, and even artificial organs using layers of human cells.

Read: Scientists 3D Print An Artificial Human Cornea Using’ Bio-ink’

How Does It Work Exactly?

All 3D printing techniques are based on the same principle: a 3D printer takes a digital model (as input) and turns it into a physical three-dimensional object by adding material layer by layer.

This is different than traditional manufacturing processes such as injection molding and CNC machining, which uses various cutting tools to construct the desired structure from a solid block.

3D printing requires no cutting tools: objects are manufactured directly onto the built platform.

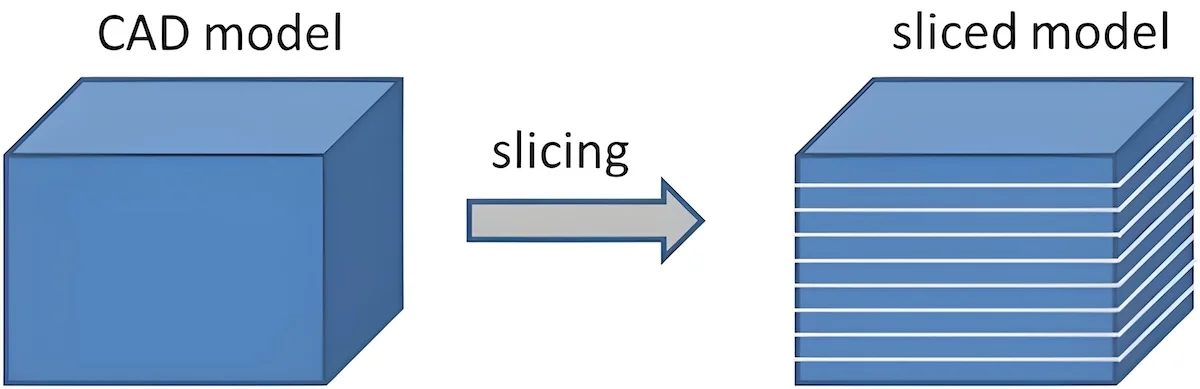

The process starts with a digital 3D model (a blueprint of the object). The software (specific to the printer) slices the 3D model into thin, two-dimensional layers. It then converts them into a set of instructions in machine language for the printer to execute.

Depending on the type of printer and size of the object, a print takes several hours to complete. The printed object often requires post-processing (like sanding, lacquer, paint, or other types of conventional finishing touches) to achieve the optimal surface finish, which takes additional time and manual effort.

3d printed endlessly swirling tree pic.twitter.com/23uj4ZIbFA

— Learn Something (@EducationalFeed) January 23, 2024

Different types of 3D printers employ different technologies that process different materials in different ways.

One primary challenge with 3D printing is that there’s no universal solution that fits all materials and applications.

Types/Processes Of 3D Printing

As per the ISO/ASTM 52900 standard, all 3D printing processes can be categorized into seven groups. Each category has its own advantages and disadvantages, which often relate to factors like cost, speed, material characteristics, and limitations on shapes that can be produced.

1. Vat photopolymerization

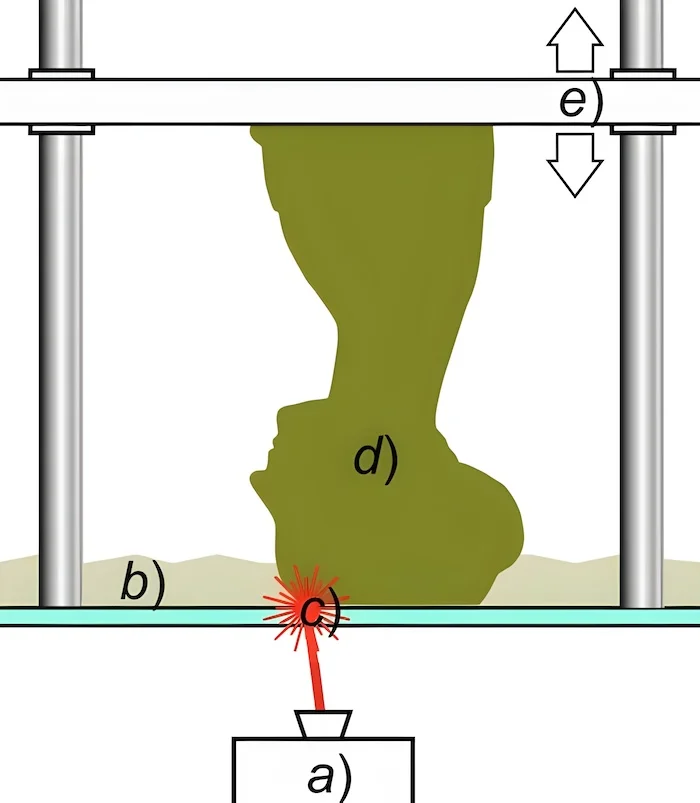

Illustration of SLA: a laser(a) selectively illuminates the transparent bottom(c) of a tank filled(b) with a liquid photo-polymerizing resin. The lifting platform(e) progressively drags up the solidified resin(d).

Illustration of SLA: a laser(a) selectively illuminates the transparent bottom(c) of a tank filled(b) with a liquid photo-polymerizing resin. The lifting platform(e) progressively drags up the solidified resin(d).

A 3D printer based on VAT photopolymerization has a container filled with photopolymer resin, which is hardened with an ultraviolet light source to create an object. The three most common forms of VAT polymerization are

1a) Stereolithography (SLA): Invented in 1984, SLA uses an ultraviolet laser to crosslink chemical monomers and oligomers to form polymers that make up the body of a three-dimensional solid. While the process is fast and can construct almost any structure, it can be expensive.

1b) Digital Light Processing (DLP): It utilizes conventional light sources such as arc lamps (instead of lasers). Each layer of the object is projected onto the vat of liquid resin, which is then solidified layer by layer as the lifting platform moves up or down.

1c) Continuous Liquid Interface Production (CLIP): It is similar to stereolithography but continuous and up to 100 times faster. CLIP can produce rubbery and flexible objects with smooth sides, that couldn’t be created with other techniques.

2. Material Extrusion

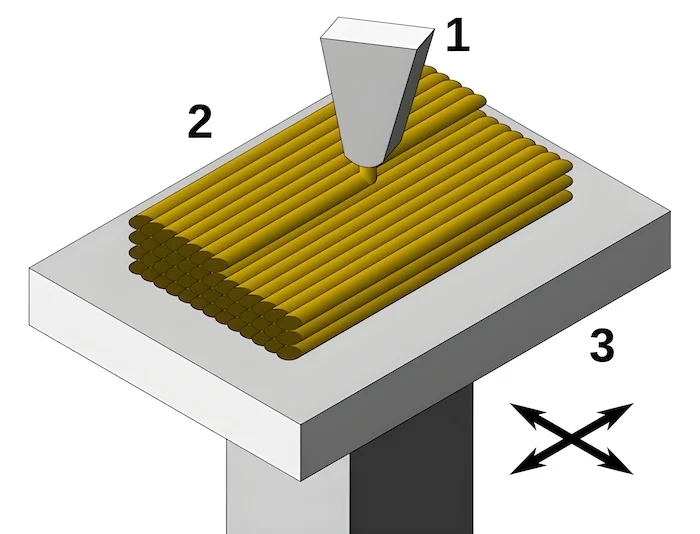

Illustration of material extrusion: Nozzle(1) is depositing material(2) on a build platform(3).

Illustration of material extrusion: Nozzle(1) is depositing material(2) on a build platform(3).

In this process, a filament of solid thermoplastic material is pushed through a heated nozzle, which melts the material and deposits it on a build platform along a predetermined path. This material eventually cools and solidifies, forming a three-dimensional object. The most commonly used techniques in this process are

2a) Fused Deposition Modeling (FDM): It uses a continuous filament of a thermoplastic material, such as nylon, thermoplastic polyurethane, or polylactic acid.

2b) Robocasting: It involves the extrusion of a paste-like material from a small nozzle while the nozzle is moved across a build platform. The process is different from FDM as it doesn’t rely on drying or solidification of material to retain its shape after extrusion.

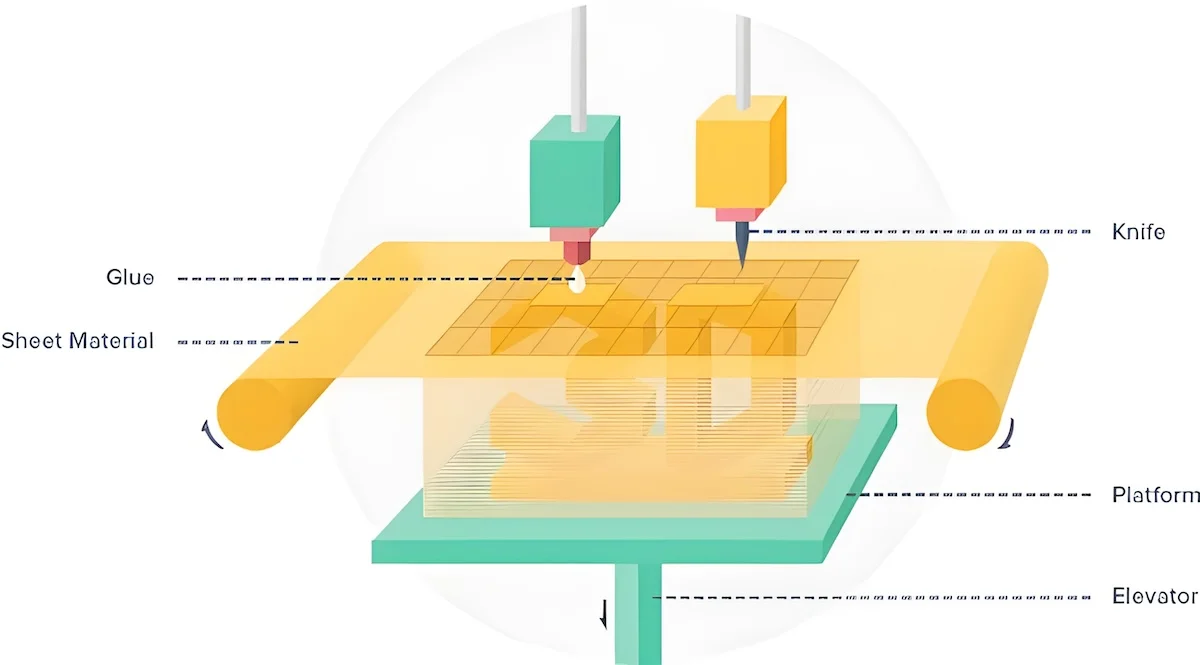

3. Sheet Lamination

Some printers use paper and plastic as the build material to lower the cost of Printing. In this technique, multiple layers of adhesive plastic, paper, or metal laminates are successively joined together and cut to shape using a laser cutter or knife.

The layer resolution can be defined by the material feedstock. Typically, it ranges between one and a few sheets of copy paper. The process can be used to make large parts, but the dimensional accuracy of the final product will be quite lower than that of stereolithography.

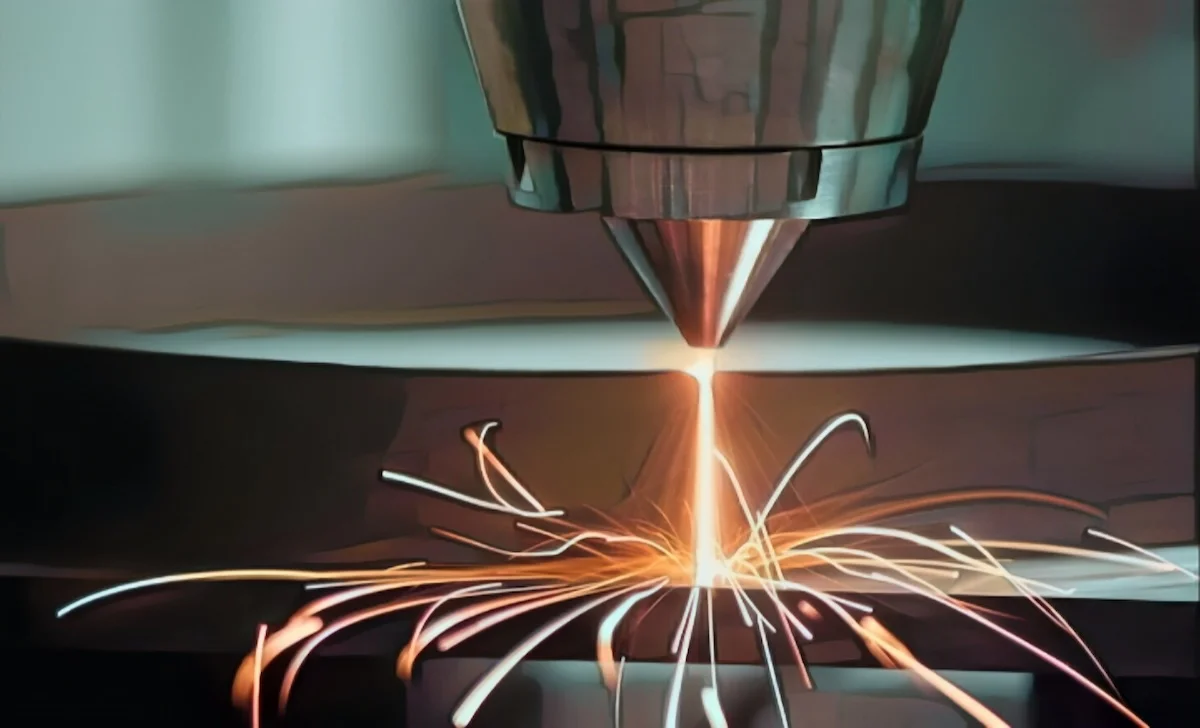

4. Directed Energy Deposition

The directed energy deposition technique is widely employed in the high-tech metal industry and rapid manufacturing. This process involves a printing apparatus equipped with a nozzle attached to a multi-axis robotic arm. The nozzle deposits metal powder onto the build platform, which is then melted using a laser, plasma, or electron beam, to form a solid object.

This type of 3D printing supports various metals, functionally graded materials, and composites, including aluminum, stainless steel, and titanium. It not only enables the construction of entirely new metal parts but also allows for the addition of material onto existing parts, facilitating hybrid manufacturing applications.

5. Material Jetting

Parts printed with the material jetting process

Parts printed with the material jetting process

Material jetting operates in a similar fashion to inkjet paper printers. In this process, a photosensitive material is applied in droplets through a small diameter nozzle and then hardened by ultraviolet light, building a part layer-by-layer.

The materials used in this technique are thermoset photopolymers (acrylics). Multi-material printing and a broad range of materials (including rubber-like and transparent materials) are also available.

Since material jetting 3D Printing can construct parts of high dimensional accuracy with a smooth surface finish, it’s an attractive option for manufacturing both visual prototypes and commercial tools.

6. Binder Jetting

A full-color print printed in sandstone with Binder Jetting | Image credit: 3D Hubs

A full-color print printed in sandstone with Binder Jetting | Image credit: 3D Hubs

Binder jetting uses two materials: a powder base material and a liquid binder.

The process involves evenly distributing the powder in layers within the build chamber. Then, jet nozzles apply the binder, effectively “gluing” the powder particles together to create the desired object.

Wax or thermoset polymer is often mixed with bonded powder to increase its strength. Once the 3D print is completed, the leftover powder is collected and used for printing another structure.

Since the technique is very similar to an inkjet-like process, it is also called the inject 3D Printing. It is mostly used for printing elastomer parts, overhangs, and colorful prototypes.

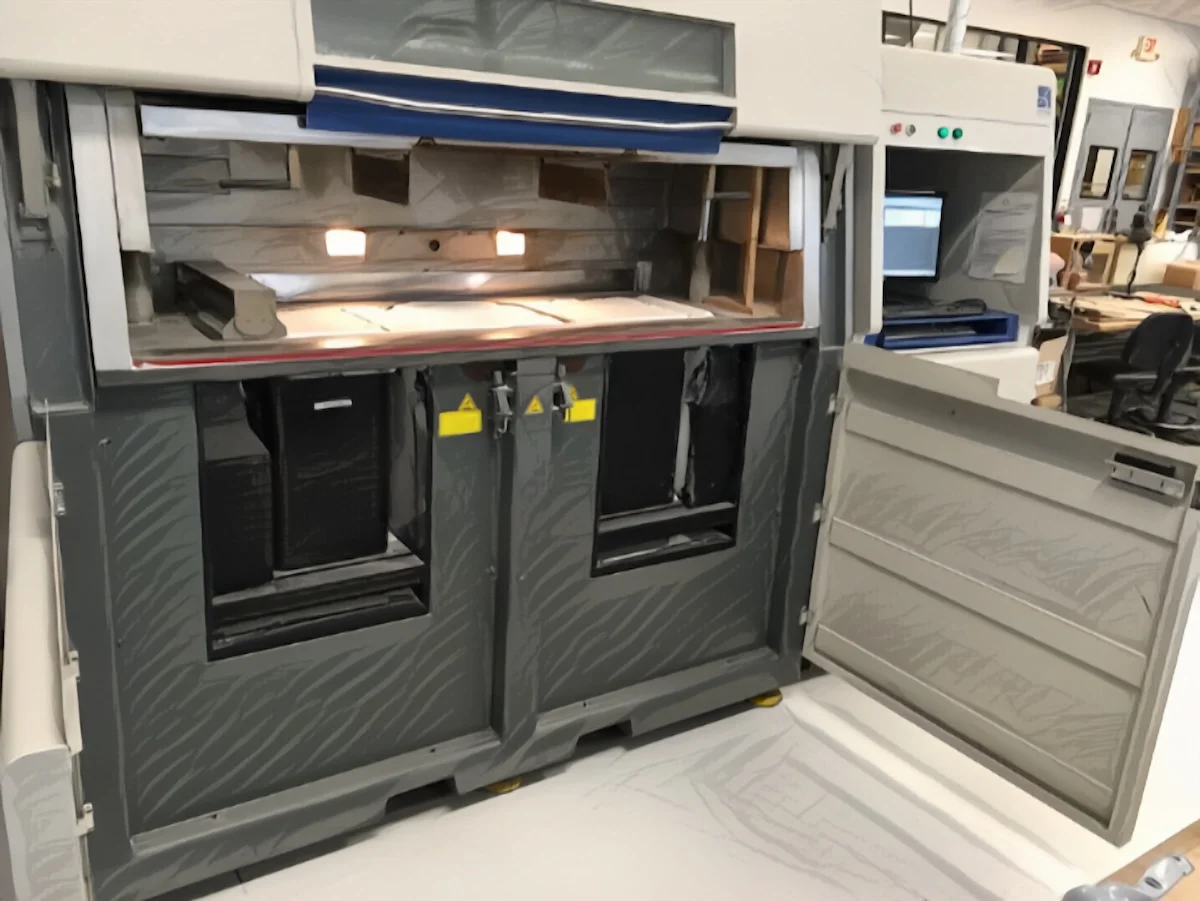

7. Powder Bed Fusion

An SLS system | DTM – 2500CI

An SLS system | DTM – 2500CI

Powder bed fusion is a subset of additive manufacturing whereby a heat source (such as a thermal print head or laser) is used to consolidate material in powder form to build physical objects. The five most common forms of this technology are

7a) Selective Laser Sintering (SLS): It uses a laser as the power source to sinter powdered material like polyamide or nylon. Here, the term sinter refers to the process of compacting and forming a solid mass of material by applying pressure or heat without melting it to the point of liquefaction.

7b) Selective Laser Melting (SLM): Unlike SLS, this technique is designed to completely melt and fuse metallic powders together. It can create fully dense materials (layer by layer) that have mechanical characteristics similar to those of traditional manufactured metals. This is one of the fast-developing processes that is being implemented in both industry and research.

7c) Electron Beam Melting (EBM): In the process, the raw material (wire or metal powder) is placed inside a vacuum and fused together using an electron beam. Although EBM can only be used with conductive materials, it has superior build speed because of its higher energy density.

7d) Selective Heat Sintering (SHS): It uses a thermal printhead to apply heat to layers of powdered thermoplastic. As soon as the layer is finished, the powder bed moves down, and a new layer of material is added, which is then sintered to form the next cross-section of the model. This technique is best for manufacturing inexpensive prototypes and parts for functional testing.

7e) Direct Metal Laser Sintering (DMLS): It is similar to SLS but uses metal power instead. The leftover power becomes a support structure for the object and can be reused for the next 3D print. DMLS parts are mostly made with powdered materials like titanium, stainless steel, aluminum, and several niche alloys. It’s an ideal process for custom medical parts, oil and gas components, and hard functional prototypes.

Read: 13 Best 3D Printing Materials

Application

In the past decade, 3D printing has made significant advancements. Its ability to rapidly produce intricate designs at lower costs has made it a vital tool across various industries. From commercial manufacturing and medicine to architecture and custom design, 3D printing has become indispensable.

Additive manufacturing techniques are now utilized to produce food products. Modern 3D printers feature pre-loaded recipes and enable users to create customized food remotely via computers and smartphones. Users can tailor the texture, color, shape, flavor, and nutrition of the 3D-printed food to their preferences.

Zero-G 3D printer sent to ISS in 2014

Zero-G 3D printer sent to ISS in 2014

In 2014, SpaceX sent the first zero-gravity 3D printer to the International Space Station. Astronauts utilize it to print practical tools like socket wrenches while in space.

In fact, many assembly projects planned for planets or asteroids will rely on materials available in nearby regions. 3D printing plays a significant role in this process of bootstrapping.

Moreover, 3D printing technology has shown promise in pharmaceutical formulations. The first formulation manufactured using 3D printing was developed in 2015, and in the same year, the FDA approved the first 3D-printed tablet.

3D printing technology has the potential to revolutionize organ transplantation and surgical practices by providing personalized solutions tailored to individual patients’ needs. For example, surgeons can use 3D-printed organ models to plan complex surgeries more effectively.

Researchers got a step closer to 3D printed organs and human tissue pic.twitter.com/DORYh67KS5

— Mashable (@mashable) January 23, 2024

Nowadays, tech companies are integrating additive manufacturing with cloud computing to enable decentralized and geographically independent distributed production. Some companies offer online 3D printing services (via website) to both private and commercial customers.

Read: 40 Best Websites to Download Free STL Files for 3D Printing

Future Of 3D Printing

The big dream of 3D printing is to have “a factory in everyone’s house.” While it might sound strange, the appeal of owning a machine capable of instantly producing a wide range of customizable items is undeniable.

Similar to how computers and smartphones have empowered billions of people, 3D printers have the potential to do the same for manufacturing.

According to GrandViewResearch, the global 3D printed market was valued at $20.37 billion in 2023, and it is expected to reach over $88.25 billion by 2030, growing at a CAGR of 23.3%.

The factors expected to fuel this market growth include intensive research and development efforts and a rising demand for prototyping applications across various industry sectors, especially automotive, aerospace, defense, and healthcare.

Read More

The 14 Best 3D Printing Software

19 Tools to Instantly Convert 2D Images to 3D Ones

3D Printer Parts: Comprehensive List Of 3D Printing Components